The Road to Net-Zero

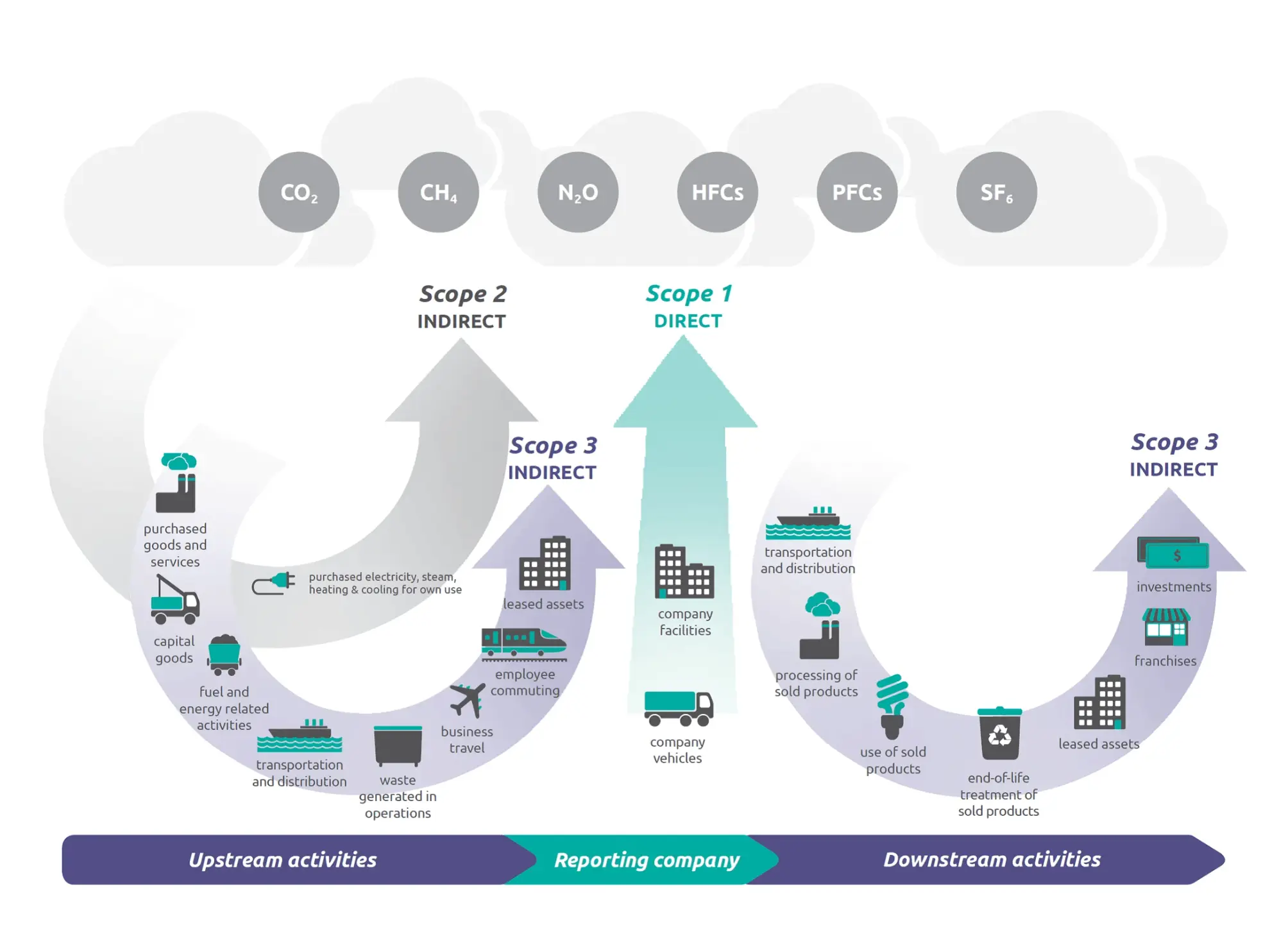

The FW Thorpe Group of companies has been officially recognised as being carbon neutral*, with systems of reduction, measurement and certified offsetting in place, since 2012. Third party assessment provides independent assurance of the Group’s long-standing commitment to sustainability across all of its operations worldwide. Being carbon neutral means that FW Thorpe Plc offsets the carbon dioxide emissions it generates (scopes 1 and 2 of the Greenhouse Gas Protocol) by its business activities.

FW Thorpe Plc is a carbon neutral company through a combination of measures. Company-wide initiatives such as energy use minimisation, self-generation of renewable energy through solar photovoltaic (PV) units, and procurement of renewable energy have reduced the Group’s carbon footprint, whilst trees in the Group’s award-winning carbon offsetting afforestation project absorb the remaining carbon dioxide produced.

FW Thorpe Plc's net-zero target has been validated by the Science Based Targets Initiative (SBTi) under the Net-Zero Standard.

In 2023, FW Thorpe Plc announced its ambitious climate target to achieve net-zero emissions by 2040 and set credible and robust science-based targets.

The SBTi has validated that FW Thorpe Plc's science-based greenhouse gas emissions reduction targets conform to the SBTi Corporate Net Zero Standard. The standard includes the guidance, criteria, and recommendations companies need to set science-based net-zero targets consistent with limiting global temperature rise to 1.5°C.

*Group companies acquired since 2012 have been assessed only since their date of acquisition.

Emission reduction targets

FW Thorpe Plc commits to reach net zero greenhouse gas emissions across the value chain by FY2040.

Near-Term Targets:

- FW Thorpe Plc commits to reduce absolute scope 1 and 2 GHG emissions 57.5% by FY2030 from a FY2021 base year.

- FW Thorpe Plc also commits to reduce absolute scope 3 GHG emissions 25% within the same timeframe.

Long-Term Targets:

- FW Thorpe Plc commits to reduce absolute scope 1 and 2 GHG emissions 90% by FY2040 from a FY2021 base year.

- FW Thorpe Plc commits to reduce absolute scope 3 GHG emissions 90% within the same timeframe.

For more information, visit: https://sciencebasedtargets.org/companies-taking-action

Carbon offsetting

In 2009, FW Thorpe Plc purchased 215 acres of farmland in Wales. To date, 179,412 trees have been planted for carbon sequestration. Based on the Group’s calculated emissions, it has been confirmed that enough trees have been planted for FW Thorpe Plc to have been carbon neutral since 2012.

The carbon capture tree-planting scheme (quality-assured by the government-backed Woodland Carbon Code) is independently certified to ISO 14064-3 and ISO 14065 standards. The Woodland Carbon Code is an independent standard, devised by a group led by the UK Forestry Commission, to certify that woodland creation projects can accurately measure how much carbon is captured and stored.

FW Thorpe has completed its woodland creation project in Devauden, Wales and has recently purchased a further 195 acres of land in Herefordshire. The land has significant potential for connecting existing woodlands for biodiversity and landscape enhancement and the transition from grazing sheep to woodland creation will have little to no impact on food security.

www.woodlandcarboncode.org.uk

Past Chairman of FW Thorpe Andrew Thorpe plants the first tree.

FW Thorpe carbon offsetting scheme in Devauden, Wales.

The final tree was planted by retiring FW Thorpe Group Director David Taylor, pictured above left with FW Thorpe Group Chairman Michael Allcock.

Renewable electricity generation

The Group has installed solar PV units on the roofs of all its UK manufacturing facilities (excluding Philip Payne), as well as at Lightronics and Famostar in the Netherlands and Zemper in Spain. These solar PV units will further reduce consumption from traditional electricity sources, enabling the Group to generate 40–50% of its own electricity usage.

All remaining significant electricity consumption in the UK and Netherlands is now derived from renewable sources.

Year projection of 12,000 tonnes CO₂e avoided by the use of solar panels

Based on 2022 conversion factors

Year projection of 50,000,000 kWh of electricity produced from solar panels

Tonnes CO₂e avoided per annum by the use of solar panels

Estimated average

kWh electricity production capability per annum from solar panels

Group company targets

- All Group companies have now been certified to the international standards ISO 14001 (Environmental Management Systems), ISO 45001 (Occupational Health and Safety Management Systems) and ISO 9001 (Quality Management Systems).

- The Group has installed solar PV units on the roofs of most of its UK manufacturing facilities, as well as at Lightronics and Famostar in the Netherlands and Zemper in Spain. In the UK and Netherlands the remaining electrical energy from the grid is now 100% from renewable electricity and 74% in Spain.

- All Group companies are required to meet ambitious targets to reduce waste to landfill.

- New product design is to follow an FW Thorpe Plc agreed Circular Design Strategy, ensuring products last even longer, use sustainable materials in their construction and are easier to reuse, refurbish or recycle at the end of their lifetime.

- All Group companies to produce Environmental Product Declarations (EPDs) for their best-selling product ranges and to evaluate the Life Cycle Assessments (LCAs) generated to assess and improve product performance.

- All Group delivery vehicles are to be a minimum of Euro 6 compliant.

- All Group companies to review their manufacturing processes and develop plans to reduce energy usage.

- The majority of Group companies have electric vehicle (EV) charging stations at the workplace.

- All Group companies to evaluate emissions from business travel and actively find ways to reduce it, without impacting business performance.

- All Group companies will target zero plastic bag and zero bubble wrap usage in its factories and aim to reach zero single-use plastic from the supply chain.

- All finished goods packaging is to be supplied from Forest Stewardship Council (FSC) or equivalent sources. Group companies will offer a return and reuse service for product packaging.

- All Group employees are to be trained in environmental initiatives.

- All Group companies to appoint a Sustainability Champion and to have a written sustainability plan.

Chairman’s Comment

“FW Thorpe Plc has a longstanding commitment to helping tackle global environmental challenges, principally through its core business of manufacturing energy efficient lighting equipment. The company has a genuine desire to become a more sustainable business.

The carbon capture tree-planting scheme (quality-assured by the government-backed Woodland Carbon Code) is independently certified to ISO 14064-3 and ISO 14065 standards. The Woodland Carbon Code is an independent standard, devised by a group led by the UK Forestry Commission, to certify that woodland creation projects can accurately measure how much carbon is captured and stored.

But our work doesn’t stop here. By assessing our carbon impact right across our value chain, and then setting science-based targets in line with the Paris Agreement on climate change, our goal is to further and significantly reduce our impact by the near term target of 2030 followed by ultimately reaching net-zero greenhouse gas (GHG) status by 2040, well before the UK’s target for achieving net zero carbon emissions by 2050.”

Mike Allcock

FW Thorpe Group Chairman